The Perfobur technology is a mechanical radial drilling with a stable channel trajectory.

Our company provides full service solution for radial drilling.

Our company provides full service solution for radial drilling.

Today, "Perfobur" has the following specifications:

- diameter of radial channels: 69 mm;

- channel length: up to 15 m;

- number of channels at one level: up to 4;

- radius of curvature of the channel: 5-7 m;

- intensity of the channel curvature: 8-10 degrees / m.

- flow rate of flushing fluid: 0.5-2 l / s.

The technology provides multiple entrance to the drilled channel for directional survey, bottom-hole treatment, deploy sandscreens in drilled channels.

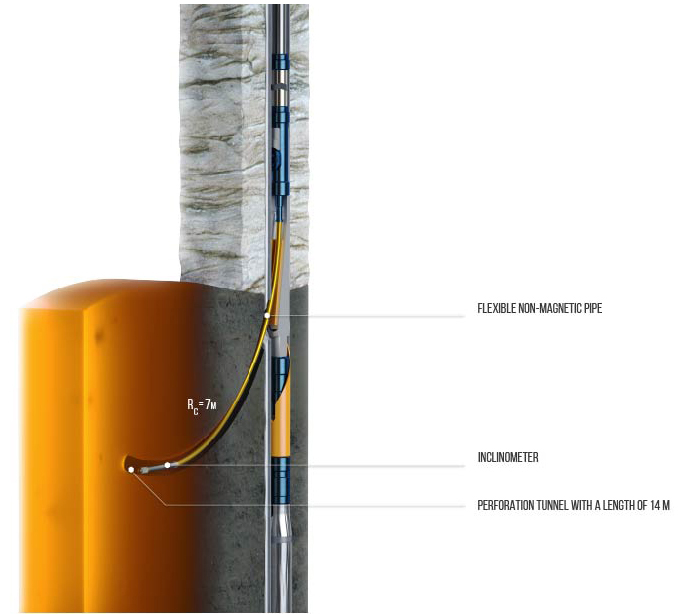

Trajectory control

To confirm the trajectory of the drilled channel, the inclinometer is run.

The assembly of the layout with the inclinometer and running is carried out in the same way as the layout for milling and drilling. Directional survey is carried out during lowering and lifting of the inclinometer in the channel through each meter. After receiving the records from the instrument, they are further interpreted and provided to the Customer.

Acid treatment of drilled channels

For wells with a limestone type of section, a jet nozzle was developed.

Using it, it is possible to carry out acid treatment of the drilled channels - acid is pumped through the holes at a flow rate of 100 m / s, which allows to wash additional channels with a length of 1 m. Injection can be done every meter.

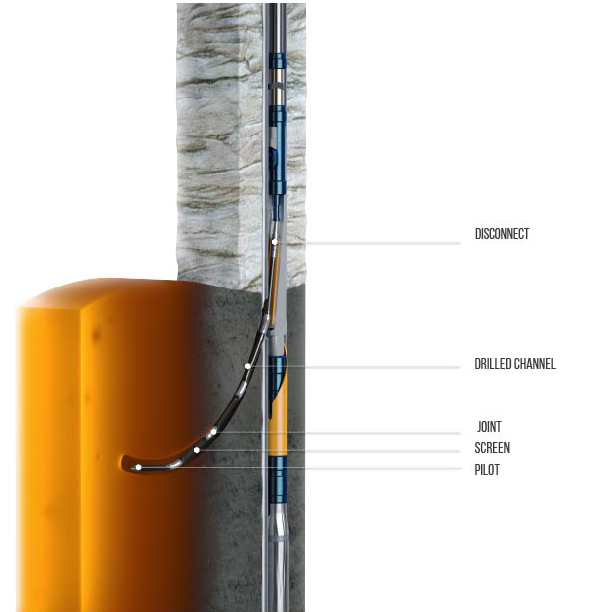

Filter release

For sandstone reservoir there is the possibility of casing drilled channels with special screens.

The possibility of multiple entry into the drilled channel allows running and installation of specially designed screen into the channel.

The channel casing with special screen prevents the channel from caving, and also increases the under-stream period of the pumping equipment in wells complicated by sand production.